In the world of Hardwood Plywood, there are many core options. Austin Hardwoods stocks 4 unique substrates for specific needs and uses. All sheet good cores are available from Austin Hardwoods are Ultra Low-Emitting Formaldehyde (ULEF).

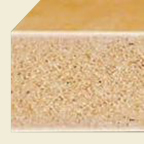

PARTICLE BOARD CORE

PARTICLE BOARD CORE

Multi-layered substrate, produced using a blend of western softwoods. The core consists of pre-consumer recycled wood fiber. The combination of sanding to extremely smooth, tight and grainless surfaces on both sides, with a controlled distribution pattern of particles in the core, results in a perfect, dimensionally stable panel.

MDF (MEDIUM DENSITY FIBER) CORE

MDF (MEDIUM DENSITY FIBER) CORE

Makes for a very smooth, consistent panel. This is a great substrate for high-end veneer and for applications when routing and shaping are required. The MDF core consists of pre-consumer recycled wood fiber.

COMBINATION CORE

COMBINATION CORE

Combination Fiber Core (CFC) veneer core combines MDF crossbands with softwood veneer innerplies. The MDF crossbands provide an ultra smooth surface to reduce telegraphing through the face, while the veneer innerplies maintain the strength and screw-holding power of a veneer core panel. This option is recommended for high-end veneers.

VENEER CORE

VENEER CORE

Veneer Core Constructed using innerplies composed of western softwoods. Veneer core panels are lightweight, dimensionally stable and have excellent screwholding capacity.

MULTIPLY

MULTIPLY

A premium quality, multi-layer, veneer core panel constructed of nearly void-free uniform birch veneer. This all-hardwood core produces an attractive uniform edge for applications requiring an exposed edge finish. Often used for drawer sides, this panel is also preferred for its consistent cutting performance.